Aerial runway code

FS120006 (Published Jan 2019, replacing version Jan 2018)

Introduction

This code is guidance for those wishing to construct and operate aerial runways within Scouting. If you choose to use equipment or techniques other than those in this document they should be of the same or higher standard. Aerial runways can only be used by members of The Scouts or Girlguiding. If an aerial runway is to be included as an attraction at a fundraising event it must be used for purposes of demonstration only, by fully-trained members of The Scouts under adult supervision. On no account may an aerial runway be made available for use by members of the public. When not in use, the runway must be immobilised as above and must remain under constant adult supervision.

What is an aerial runway?

An aerial runway is a rope slide that stretches between two fixed points, and is angled sufficiently to enable a pulley block to slide down its length using gravity as its only source of propulsion. An aerial runway does not use metal cable as this is then defined as a zip wire and falls within the high ropes rules.

Where to position an aerial runway

The location and position of the runway will help with its operation and also ensure that the group enjoy using it. Natural features like trees and the slope of the ground will determine the length of run and the speed of descent. However the height and angle of the slope should allow for a safe and steady descent.

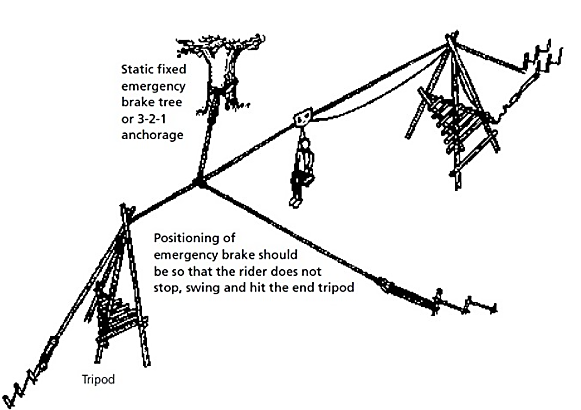

The illustration below shows a typical construction.

Supervision

The planning, construction and use of an aerial runway should be directed and constantly supervised by a responsible and competent adult member. Testing the system is a responsibility of the person in charge of the activity. They must also ensure that all equipment is checked prior to and regularly during use to ensure that it is fit for purpose.

Equipment

- Rope (the main hawser) – the hawser must be synthetic as natural fibre ropes can’t be tested to assure of their suitability. Under a load of 1000 kg (10 KN) the rope must not stretch more than 1.25%, there is no longer a recommended minimum diameter. Ropes must be checked for wear and tear prior to use and used within the load limit identified by the manufacturer.

- Travelling block – this is a metal double pulley block which runs along the rope allowing the participant to move from one end of the runway to the other. Only metal double pulley blocks designed to carry a human. These should only have closed ring shackles to attach the seat and braking lines, anything which has been adapted from another purpose must not be used.

- Seat – various types of seat are available, from manufactured seats designed for this use to a homemade seat, in either case they must be tested to carry a suitable weight for the activity intended to be undertaken and so that the passenger does not fall out of the seat whilst in use.

- Blocks and tackles used to tighten the runway – these are used to tension the main rope, no hooks should be used within this system, only rings and closed eyes.

- Wooden or metal poles (pickets and spars) – these should be checked to be in good condition prior to use, with no cracks or rot and should be of an adequate length for the construction proposed. A minimum size of 1 m x 75 mm and lengths no shorter than 1.5 m. Care should be made when driving the posts into the ground to not cause damage through this process. An appropriate proportion of the post should be within the ground to create suitable anchor to the system.

- Cords – other cords should be available to use as brake systems.

- Sack or old canvas – this is used to protect any natural features in the area.

All equipment must be used, stored and maintained using the guidance provided by the manufacturer. It's good practice to keep a written log relating to the use of the equipment, this should include: date of purchase, usage, inspections carried out and maintenance, along with method of disposal for time-expired or damaged equipment.

Construction

The main rope can be run between two trees or between two tripods (as outlined earlier in this guidance). If using trees they should be checked to ensure that they are suitably sturdy for the proposed purpose.

If working at height in the construction of the runway appropriate precautions must be taken to limit risk.

Sheer legs can be used to take full advantage of the angle of the slope as outlined below, making sure that it is secured by the feet of the two legs being buried to a minimum depth of 150 mm.

A tripod system can also be used as they can give greater stability when guylines are applied.

Tensioning the main rope is a major part of the construction and ongoing maintenance of an aerial runway as the rope will inevitably slacken as it is used and this needs to be monitored and tightened at regular intervals. It is recommended that to tension the system a luff tackle made up of one single block attached to an anchor and one double block attached to the main rope is used. Once appropriate tension is achieved then the system needs to be secured using a round turn and two half hitches to the anchor point.

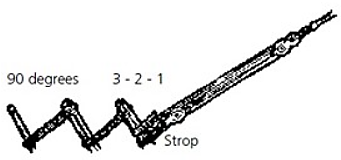

There are a variety of different types of anchorage systems that can be used, a few are pictured below but should be fully researched and a decision made based on the appropriateness for the system being used.

3-2-1 anchor

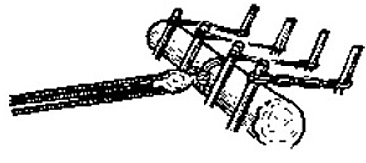

Log and picket anchor

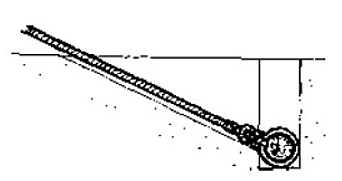

Dead-man anchor

It is really important to have a robust braking system on the runway, allowing the passenger to come to a stop gently. The main brake must bring the travelling block to a steady stop, no system which brings an immediate stop is suitable. A suggested system is pictured.

An emergency brake is also required allowing manual braking if the main brake fails, preventing any collision with the end of the system.

All braking systems must be tested before the system is used.

Testing

Before the system is used, it should be fully tested, putting the system under higher strain than that of the passengers using the system. Tests must be under the supervision of a competent adult and with plenty of spotters throughout the system to identify any issues and report back to the person in charge.

- Attach a temporary rope to the empty seat. Starting at the top of the run, a vigorous bouncing strain from ground level should be applied. This should be repeated throughout the entire length of the run, especially around the mid-point where maximum sag in the main rope will be experienced.

- The seat should then be drawn to a convenient point and loaded with at least two five gallon containers full of water. This load represents a body weighing approximately 50 kilos (choose an appropriate weight for those intending to use the system). At the mid-point of the runway, the sag in the main rope under load must not allow the feet of a passenger to strike the ground. If this happens, adjust the tension on the main rope.

- The loaded seat should then be drawn to the top of the runway. The speed of descent and the main braking system should now be tested. The load should be brought to a stop short of the lower sheer legs or tripod with an adequate margin of safety. At the same time, the elasticated shock cord should not be allowed to extend beyond twice its natural length.

- Finally, the main braking system should be disconnected and the emergency brake tested, again using a loaded seat running from the top of the runway. The position of the emergency brake operators, if used, should be marked so that there is no tendency to drift towards the bottom of the runway during normal operation.

- After all these tests, all knots, lashings, anchorages, pickets and so on should be thoroughly inspected.

Rules relating to aerial runways

Rule 9.12.5 High Ropes Activities

Additional information